Description

New 5-ply tonearm beam

New 5-ply Groove Runner S Top and Lower beams possess much higher acoustic linearity than their predecessor.

Top and Lower beams are bonded and riveted to ensure optimum rigidity combined with linear resistive damping.

Couple the above with the inherent critical damping of the beam construction and we have an ideal platform to support the cartridge.

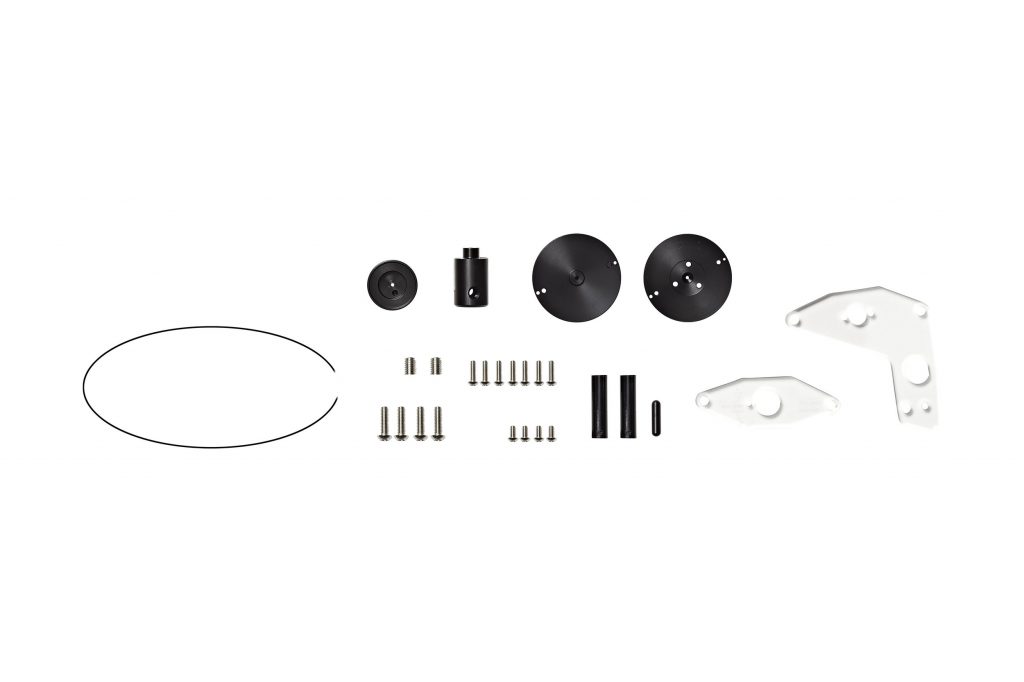

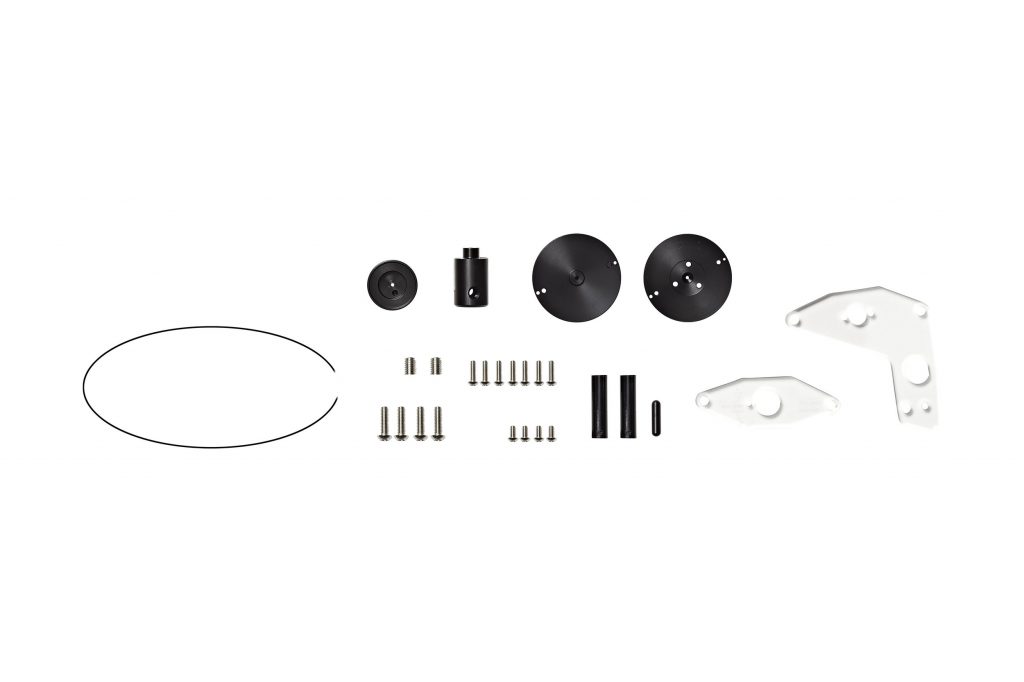

Improved tonearm bearings

Groove Runner S Kevlar thread bearing is now adjustable for tension and azimuth. With the new Azimuth Adjustment Counterweight Screw, finer azimuth setting is made easier and more accurately to enhance cartridge performance.

New higher tolerance super polished main bearing spindle

DG-1S utilises a higher tolerance matched main bearing with super polished bearing spindle for ultra-smooth, noise-free running. The new bearing ensures even quieter background further enhancing dynamic range and resolution.

New Motor Drive software

The new motor drive software facilitates a three step factory adjustment of the motor torque and noise setting with a final minimum noise adjustment. The new software allows an initial setting of the sine wave voltage and fixes it to establish the reference. A separate, independent cosine wave voltage setting with phase angle adjustment ensures lowest noise and vibration from the drive motor.

TECHNOLOGY

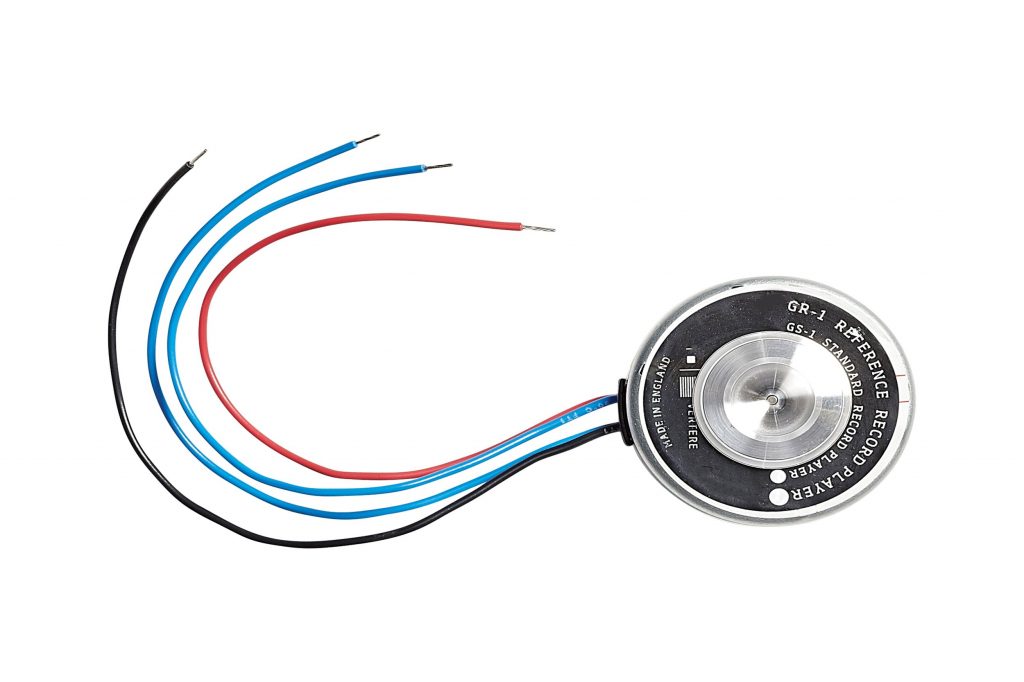

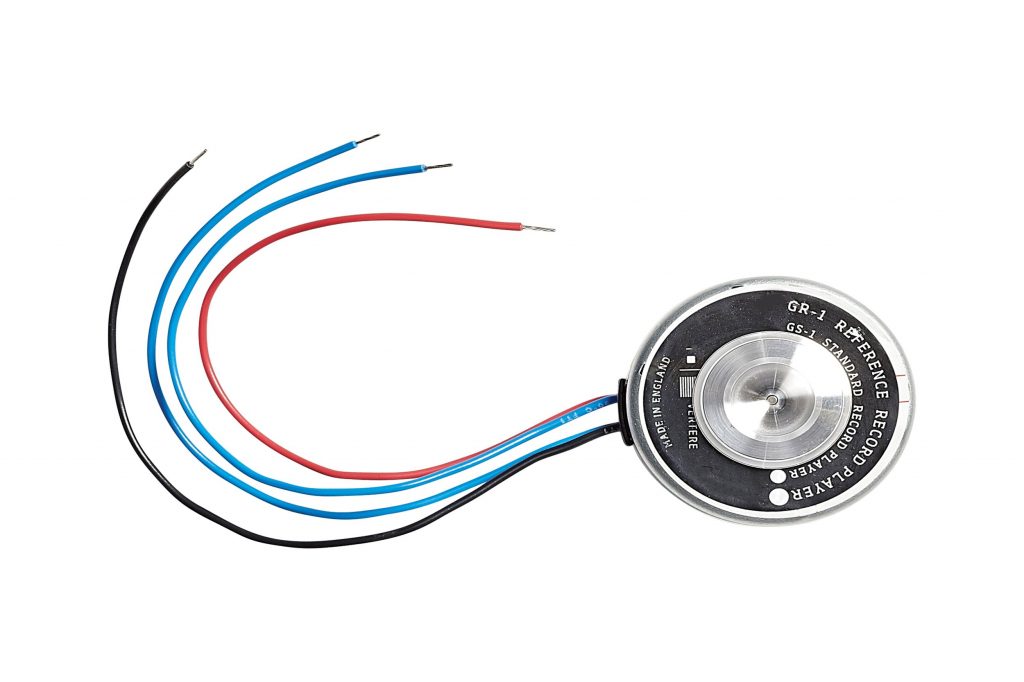

The Motor Drive

In case you thought the motor’s only job was to make sure the record rotates at the correct speed, think again: as the only source of energy for the signal generated by the cartridge, in short the music we hear, it’s arguably the most important component of any record player. The DG-1S’ motor system is derived from that developed for the flagship RG-1 Reference Motor Drive and it is as sophisticated as it is innovative yet it sits hidden away inside the main steel chassis. DG-1S’ advanced motor drive incorporates a programmable microprocessor with a D/A convertor to provide low distortion sine and cosine waves that are used to turn the motor. The signals generated are then amplified to the correct level using two bridged-balanced amplifiers. The amplified drive signals then feed and control every move of the motor to ensure a linear, smooth turning of the drive pulley. The motor itself is a low voltage Precision Synchronous design, individually ‘tuned’ for the lowest noise by adjusting the microprocessor controls during manufacture. A copper foil and a stainless-steel cover provide shielding of both inward and outward interference to ensure the best possible performance. The result is accuracy and precision of drive to the motor that ultimately is responsible for making of the music. There is a service panel on the underside of the chassis that allows connection to the motor drive PCB for future adjustment and software upgrades.

The Platter

Drive to the platter is via a precision machined aluminium alloy pulley on the motor and a bespoke silicon rubber drive belt for smoothness and durability, while electronic speed change, via a switch to the rear of the plinth top-plate, adds to the ease of use and removes any need for belt-handling. Like the pulley, the platter itself is also precision-machined alloy, to the top of which is bonded a PETG record interface mat. On the underside an aluminium alloy bonded disc controls platter resonance while a cork/Neoprene/nitrile bonded disc protects the acrylic plinth from accidental damage that could be caused by the platter inadvertently touching the plinth.

The Main Bearing

The platter fits onto the super polished stainless-steel spindle that rides on a precision tungsten carbide ball in the high tolerance DG-1S main bearing housing. The complete bearing assembly is long-term lubricated for longevity and ease of use. This avoids regular repeated recharging of the bearing lubricant, which is essential to prevent premature wear and damage – another example of simplifying record player maintenance and optimising performance. The new super polished precision bearing delivers even lower noise, lower rumble and higher rotational stability all essential for accurate playback of records.

The Groove Runner S Tonearm

The DG-1S arm is uniquely Vertere and differs from conventional thinking in its use of a flat profile in place of the usual tube. Conventional arms use tubes for stiffness, but these can introduce all kinds of problems with high Q resonances and thus the need for extra damping – costly and complicated. The DG-1S’ bonded double five-layer, non-resonant tonearm beam avoids these problems. In addition, in place of conventional tonearm cabling, a flexible PCB is sandwiched into the arm to shield and ‘carry’ the signal from the cartridge to the output terminals. Completing the arm are a stainless-steel counterweight with azimuth adjustment screw and a fine adjustment tracking weight, to provide a total solution that’s as simple and elegant as it is innovative.

The Silent Thread Bearings

The bearings allowing the arm its horizontal and vertical movement on the Groove Runner are also innovative: there aren’t any – well, not in the conventional sense!

Many solutions have been sought over the years for ‘precise’ bearings, which need to be small and hopefully not too noisy. For the Groove Runner, Vertere has developed an elegant, innovative solution borrowing ideas from the Reference Tonearm: twisted nylon (hundreds of 3 microns thick twined Nylon strands) and high strength Kevlar threads. Utilising one nylon thread for movement in the horizontal plane, and two Kevlar ones for the vertical motion replace the conventionally used ball-race or gimbal type bearings.

These threads have many advantages, not the least of which is simplicity: they exhibit none of the Stiction – or initial resistance to movement – of conventional bearings, are super-light and noiseless. In addition, the twist of the nylon thread smartly provides the anti-skate force without any other moving or sliding part. Finally, design geometry of these bearings cleverly provides the optimum support rigidity for the cartridge during playback to ensure lifelike dynamics that is only achievable from much costlier designs.

The Plinth Structure

Similar to the Groove Runner tonearm the DG-1 plinth is a three-layer sandwich construction using non-resonant cast acrylic to form the main plinth and the sub-plinth – clean and sophisticated. This three-layer design incorporates the control button, the speed indicator and the user-selectable standby mood-lighting, as well as six bespoke silicon rubber suspensions that isolate the sub-plinth from the main plinth and chassis. The sub-plinth isolation effectively ‘distances’ the bearing/platter assembly and the tonearm/cartridge from the main plinth structure. The main plinth assembly sits on a steel chassis, chosen for optimal stability, housing the motor drive circuit and the motor all supported by three adjustable feet.

The DG-1S’ formed polycarbonate dust-cover clips onto its hinges that are neatly integrated into the main plinth for a sleek and modern profile.

SPECIFICATIONS

DG-1S TURNTABLE

Type

Belt drive

Motor

24 Pole Synchronous

Acetal Spindle Thrust Bearing

Motor Mount

Axially De-coupled

Pulley

Super Precision Aluminium Alloy

Drive Belt

Bespoke Silicone Rubber

Platter DG-1

Precision Machined Aluminium Alloy

PETG Bonded Record Interface Mat

Underside Bonded Resonance Control Disc and Bonded Protective Cork/Neoprene/Nitrile Disc

Bearing Spindle DG-1

Non Magnetic Stainless Steel

Super Precision Machined and Polished

Roundness / Concentricity

< 5 Microns

Bearing Housing

Brass

Super Precision Machined

Bore Tolerance < 5 Microns

Super Precision Tungsten Carbide Ball

Plinth Structure

3 Layer Cast Acrylic

Middle Clear Plinth, Internally Illuminated

Isolation System

6 Point, Bespoke Silicone Rubber

Support Structure

Black Coated Zintec Steel Chassis

Three Adjustable Feet with Resistive Felt

Motor Drive

Advanced Microprocessor Controlled

Fully Programmable with Motor Noise Reduction

Bridged Balanced Motor Output Amplifiers

Speeds

33.3 and 45 rpm (+/- 0.2%)

Electronically Selectable

Dust Cover

Bespoke Formed Tinted Polycarbonate

Dimensions (W x D x H)

469 x 384 x 130mm (including dust cover)

Power Supply

Wall Adaptor Type

UK, US, EU and AUS Exchangeable Plugs

100 – 240 Vac with 1.5m Cord

Finishes

Black and white gloss

Weights

8kg – Net

GROOVE RUNNER S TONEARM

Type

Fixed Axis Bearing

Effective Length

240mm

Overhang

17.5mm

Offset Angle

22.9°

Bearing Structure

One Twisted Nylon 6.6/6 Thread – Horizontal Motion

Two High Strength Kevlar Threads – Vertical Motion

Counterweight

Stainless Steel

With Fine Azimuth Adjustable Screw

Front Beam Small Weight

Stainless Steel Block

Fine Tracking Weight and Arm/Cartridge Resonance Tuning

Internal Wiring

Gold Plated Flexible PCB

with Vertere Gold Plated Cartridge Tags

One Piece from Cartridge

To Output

RCA Sockets

Weight

310g

Reviews

There are no reviews yet.